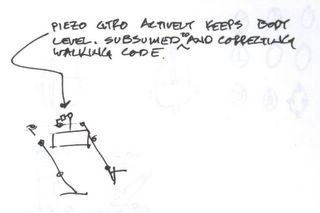

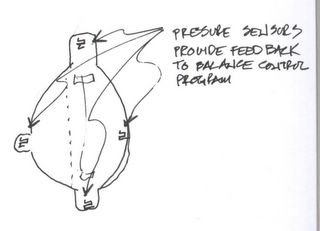

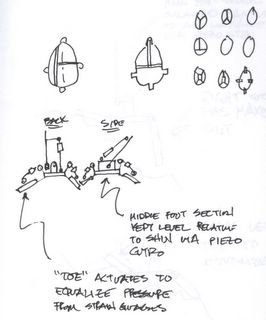

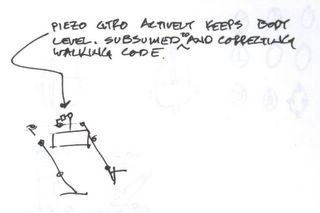

The kind of ballance sensors we've discussed are piezo gyros and accelerometers.

Knewt is scheduled to recieve these in it's next phase of development. Len Harrelson of the Southern Poly Arial Robotics Group will advise on the use of these sensors. They use them to stabalize their un-manned helicopter during the

IARC competition.

Dale Heatherington has alot of experience with using piezo gyros in his bots. He tends to hack into the sensor and use outputs that weren't neccessarily intended to be used.

Knewt will test coding scenarios of these instruments for use on Knossos.